Engineering services is our business - Please choose your topic ...

- Industrial Engineering

- Process Engineering

- Quality Engineering

- Consulting

- Seminars

- Business Development

-

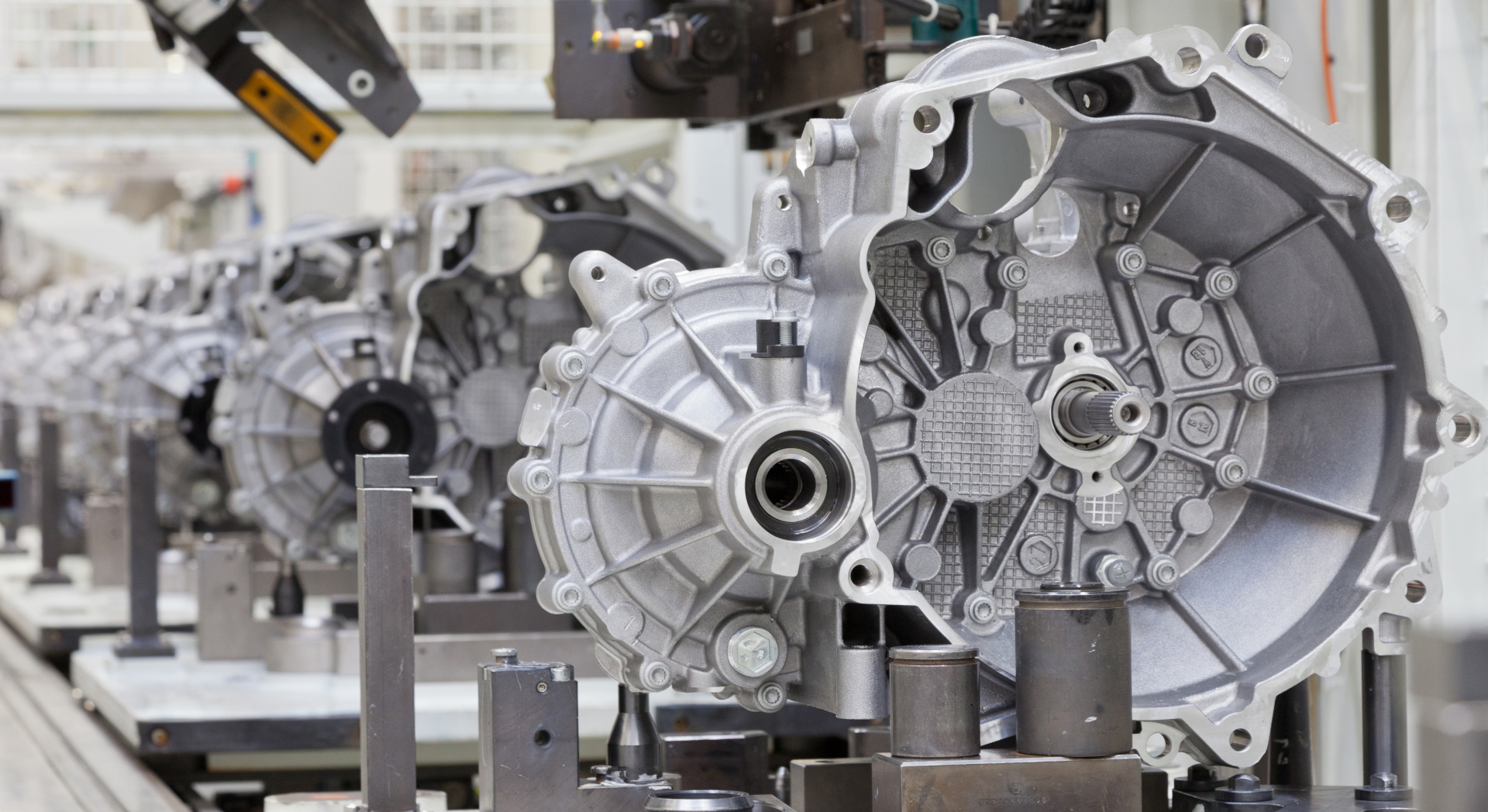

Industrial Engineering

Planning and design of production facilities | With focus on automotive light metal casting and subsequent processes. We have extensive knowledge of tools, industrial processes and furthermore a wealth of manufacturing experience. The lowest possible manufacturing costs while maintaining the required component properties is a priority.

Project planning of technical building equipment | Especially for light metal foundries we plan and dimension the cooling water supply with heat recovery as well as the design of air conditioning systems for heating and/or cooling.

Optimization of production structures | Productivity gain, overall plant efficiency (OEE), reduction of manufacturing costs, capacity extension, restructuring.

Relocations | Planning of relocations with a sound of industrial engineering and QM expertise.

Workshops | Workshops are a very efficient kind of support projects such as workshops considering OEE-increase, reduction of cycle time, restructuring of production lines, reduction of production costs, increase efficiency of the production-system, reduction of scrap rates and casting suited component design.

Sounding Board | We are available as a „sounding board“ for your project team such as for project reviews. The costumer identifies - short term - important additional information and/or gets a second opinion provided by an independent partner.

Your contact for industrial engineering and production planning

Fabian Prügner

Phone: +49 6224 9908 0

-

Process Engineering

We support you in projects related to improvement of production processes. Our focus is on light metal casting and subsequent processes.

Optimization of production processes and production equipment | Increasing output, improvement of product quality, reduction of scrap rates, improvement of process repeatability, reduction of production costs, the increase of plant OEE and related topics.

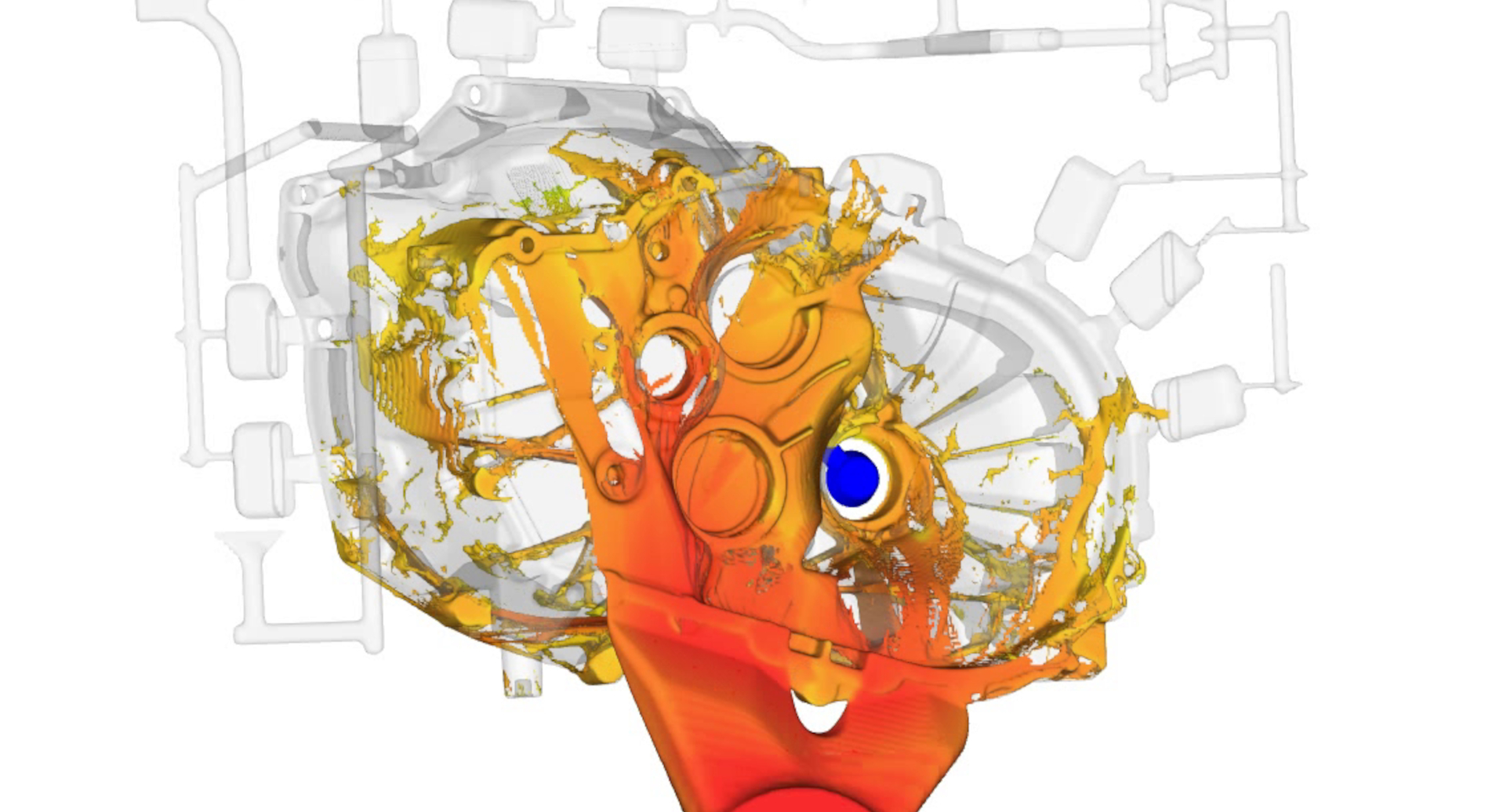

Casting suited component design | We support your component development by early reviews of the component geometry with consideration of casting suitability, such as:

- Temperature field analysis

- Determine the casting position (position of the component in the mold)

- Development of the casting system (mold filling and feeding)

- Casting suitable optimization of the component geometry by carrying out mold filling and solidification simulation

- Reporting

Developing casting processes | We plan your casting process, beginning by checking the geometry of the component up to supporting your production staff during implementation and ramp up.- Temperature field analysis

- Determine the casting position (position of the component in the mold)

- Development of the casting system (mold filling and feeding)

- Conceptual design of the mold and consulting the mold manufacturer under consideration of casting suitable design

- Supporting your production staff during ramp up

Casting defect trouble-shooting | We analyze casting processes and casting defects with special tools and high grade expertise to define adequate countermeasures. PE effectively manages this topic by running own casting simulation software. It allows us to perform in house temperature field, mold filling and solidification analysis.Your contact for topics related to the casting process

Martin Braus

Phone: +49 6224 9908 0

-

Quality Engineering

Designing your quality management system as well as supporting you by operative quality management is our business. Especially for casted parts we offer extensive know-how.

Quality planning, ramp-up management and phase-out management | Operative quality management during product development process, serial production up to EOP (End-Of-Production).

Supplier management and supplier development | Supporting your supplier to effectively close quality gaps and reach satisfying shipment rates.

Task force | Intensive on site project management to overcome critical technical situations.

Quality management system | Consulting, designing and optimization of QM-systems regarding international revisions in particular ISO 9001:2015 and IATF 16949:2016.

Training | Seminars focusing on Quality Engineering.

Your contact for QM topics and supplier management

Martin Braus

Phone: +49 6224 9908 0

-

Consulting

Technical consulting on all aspects of series production with a focus on efficiency and costs.

- Restructuring | Operational Execllence

- Operational Due Diligence

- Digitalization strategies

- Manufacturing footprint strategy (make or buy)

- Identification of savings potential

- Taskforce and PMO

- Cost and value engineering

Your contact for strategy and consulting topics

Fabian Prügner

Phone: +49 6224 9908 0

-

Seminars

Project Engineering offers practice-oriented seminars in the field of:

Light Metal Casting | Seminars imparting the casting methods gravity, low pressure and die casting as well as seminars on casting simulations and casting defects.

Quality management | Seminars on „PPF procedures“, „special features“, 8D, FMEA and Q methods.

Project management | Seminar topics are failure management, leadership and personality, conflict management, self-organization of executives, systemic project management.

We collated in 2014 our seminar offering by establishing Project Engineering Campus. The Seminars are available in German or English.

They can be located in Heidelberg or take place as in-house seminars at the customers site. Those seminars allow to be tailored individually to the customers requirements.

Seminar capacities are limited to 15 people. Employees and managers in quality- and supplier management, purchasing, development, production and industrial engineering are the most typical participants.

Your contact for seminars and workshops

Timo Ehnert

Phone: +49 6224 9908 17

-

Business Development

Are you aiming to attract German and European OEM as customers for your products?

We know the culture and rules of OEM‘s and can support you efficiently!

- We act as your German or European representative,

- establish and maintain contacts with potential customers,

- act as local contact for your customers,

- support you and your employees in the various project phases,

- train your employees in the customer processes and behaviors,

- support you in qualifying your company as an approved supplier.

Your contact for international business

Detlev Hessler

Phone: +49 6224 9908 21